Providing precise, flexible, and secure solutions for your filling process

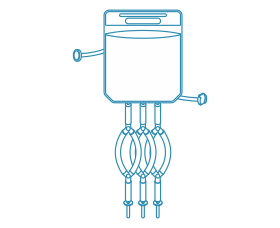

Our single-use sterile filling bags include high-level buffer bags, filling tubing, and filling needles as components, utilizing a super-clean production process to ensure the cleanliness of the single-use filling bags. As modular components in the formulation filling process, these bags offer advantages such as reduced contamination risk, increased operational flexibility, and shortened changeover times, expediting the drug development and market entry processes.

Compared to traditional stainless steel systems, single-use systems offer the following advantages:

- More flexible operation

- Higher safety standards

- Shorter production cycles

- Lower initial investment costs

The filling bags produced by LePure Biotech are highly regarded. As modular components in the process of single-use filling systems, they combine flexibility with outstanding safety, meeting regulatory demands for pharmaceutical companies to continually reduce the risk of cross-contamination and decrease the need for cleaning validation.

Composition

Filling Tubing:

- Components: Includes tubing for liquid input before the pump, pump tubing, and liquid output after the pump

- Pump Tubing: Critical segment squeezed inside the filling pump (peristaltic pump), influencing filling precision

- Structure: Each filling pump typically has two roller channels with 4-8 rollers each

- Convergence: Two tubing sections converge into a single channel

Reasons for Choosing Us

Comprehensive Support

- Our team has expertise in designing over 500 types of filling bags

- With an average of over 7 years of industry experience, LePure Biotech delivers the most practical and customer-oriented single-use filling solutions

- Beyond design services, the team offers comprehensive technical support

Ultra-Clean Platform

- “C+A” level environmental control

- Pre-rinsing of Critical Raw Materials

- Unidirectional flow of materials

- Multi-dimensional testing

Parameters

Note: 100% can be customized flexibly, please contact each regional sales manager for details.

| Item | Configuration Information |

|---|---|

| Isolator | BETA Bag (Optional) |

| Bag Volume | Range: 2L-50L (U-HP, FI) |

| Liquid Inlet Tubing Connection | Sterile connectors or heat-sealable tubing |

| Breather | Air filter |

| Filling Tubing | Quantity: 1-16 units |

| Filling Needle | ID Range: Min 0.5mm, Max 7.0mm |