Tailored culture medium solutions that are highly adaptable and flexible for your specific needs

LePure Biotech’s subsidiary, QuaCell Biotech, is dedicated to exploring a new aesthetic in cell culture in collaboration with our customers. For those who already understand their required culture media and anticipated outcomes, we employ statistical analysis software such as Design of Experiments (DOE) to conduct tests and assessments in areas such as optimization of culture media formulations, preparation of culture media, quality standards, adaptability of cell lines, yield, and quality parameters.

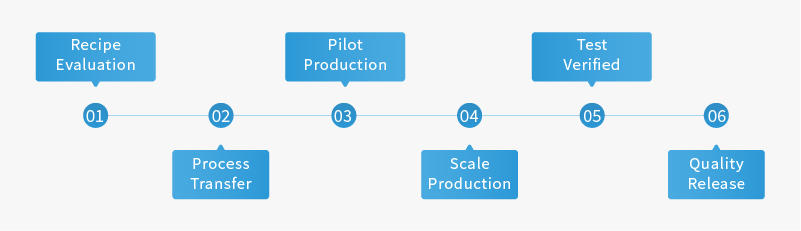

Based on your processes, we offer flexible services for the development or optimization of culture media formulations, and we provide process transfer solutions to meet your industrialization needs.

Our Advantages:

- Customized solutions for dry powder and liquid culture media

- Comprehensive quality testing and cell culture validation support

- Scalability with end-to-end process transfer solutions

- Seamless GMP-compliant supply solutions to meet industrialization demands

Medium Development cGMP Manufacturing Platform

Liquid to Powder & Testing

- Formulation of base and supplementary culture media

- Development of cultivation process schemes

- Research and development of powder preparation

- Execution of experiments

Powder & Testing

- Confirmation of powder development

- Research on MST (Manufacturing Scale-up Technology)

- Trial production of MST powder

Powder & Delivery

- GMP-like trial production of powder

- Establishment of release standards

Our Services

Own Culture Medium Database

- Locate key materials and crack the black box of formulas

- R&D and MST are linked to seamlessly connect GMP production

HTS High-throughput Screening System

- Equipped with various culture systems and equipment including deep well plates, TPP, shake flasks, and reactors

- Professional culture medium screening team, rolling experimental platform, capable of executing 600+ procedures at the same time

- Automated weighing system enables complex DoE design

Data analysis

- One-stop data processing analysis + recipe recommendation

- Preprocessing, statistical analysis

- Formula score sorting and optimization direction recommendations